Reactors

Tubular Reactors

Phoenix™ Flow Reactor

Scope

- High Pressure, High Temperature Continuous Flow Reaction Platform (hydrogenation, oxidation, carbonylation, catalyst testing)

- Modules

- H-Genie®: On-demand in-situ hydrogen generator

- Hastelloy Phoenix™ Flow Reactor: High temperature reactor

- Gas Module: External Gas Dosing system

Operating Parameters

- H-Genie®:

- Purity: 99.99% (4.0) hydrogen

- Pressure: 1 – 100 bar

- Flow rate: up to 1 NL/min

- Phoenix™ Flow Reactor:

- temperature: 450 °C

- pressure: 200 bar

- Multi-phase Heterogeneous, Homogeneous catalytic reactions

- Wide range of catalytic column sizes, loop reactors

- Gas Module Plus:

- Outlet Pressure: Max. 100 bar

- Accurate gas dosing for: compressed air, O2, CO, ethylene, SynGas, CH4, C2H6, He, H2, N2, N2O, NO, Ar, CO2

- 100-1000 NmL/min

- THS System Controller® and THS ReAction®

- Automated reaction sequencing, user determined safety-triggers

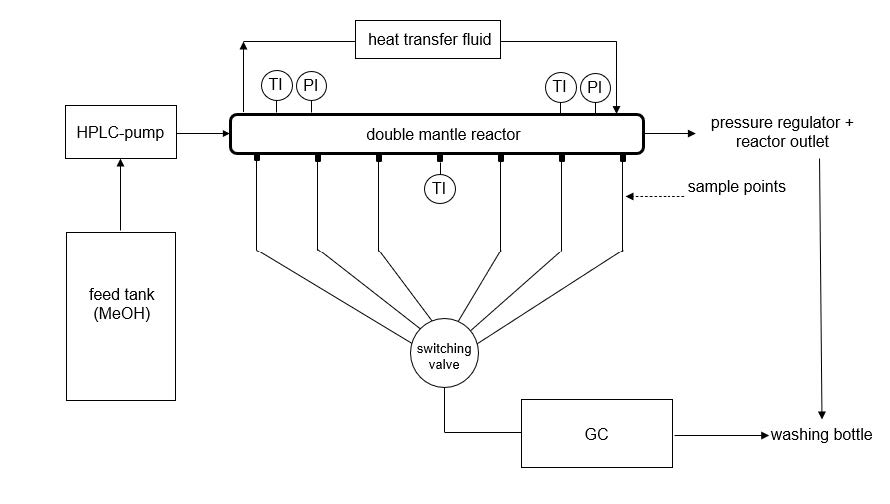

Fully Automated Continuous Tap Reactor with Liquid Sampling Points

Features of the Tap Reactor:

- Reactor volume: approx. 20 ml (internal diameter: 10 mm, length of reactive zone: 300 mm)

- Maximum temperature up to 250 °C

- Maximum pressure up to 150 bar

- Sampling possible during operation (liquid)

- 6 sampling points

- Fixed bed reactor

- Heterogeneous catalysis

- Temperature measurement possible in catalyst bed

- Stainless steel construction

- Online analytics of liquid phase by gas chromatography

- Fully automated: pressure measurement, volume flow, temperature, program-controlled sampling

- Optimal for catalyst screenings, solvent screenings, feasibility studies etc.

Contact

Christian Schwarz

Head of Miniplant Laboratory & Testing Fuel Department

Contact

Alina Greve

Head of Miniplant LAB & Synthesis Department

Need additional analyses?

Our laboratory has been accredited since 1998 for the analysis of numerous fossil and biogenic fuels.